The processing of residual feeds in fluid catalytic cracking (FCC) units poses significant operational challenges, especially when it comes to feeds with high metal concentrations, high carbon residue content and complex molecular structures. Under these conditions, the efficient diffusion of higher molecular weight hydrocarbons into the catalytic particles may be compromised, resulting in conversion losses, increased coke formation, and lower yields of desired products.

To address these limitations, Fábrica Carioca de Catalisadores S.A. offers the UPGRADER™ family of catalysts. These catalysts were specifically designed. focusing on the efficient cracking of heavy feeds and maximizing the bottoms conversion. Its technological differential is based on three main pillars: high accessibility, an active high-performance matrix, and excellent resistance to contamination by metals such as nickel, vanadium, and iron.

Graph 1 – Average iron content.

Source – FCC S.A.

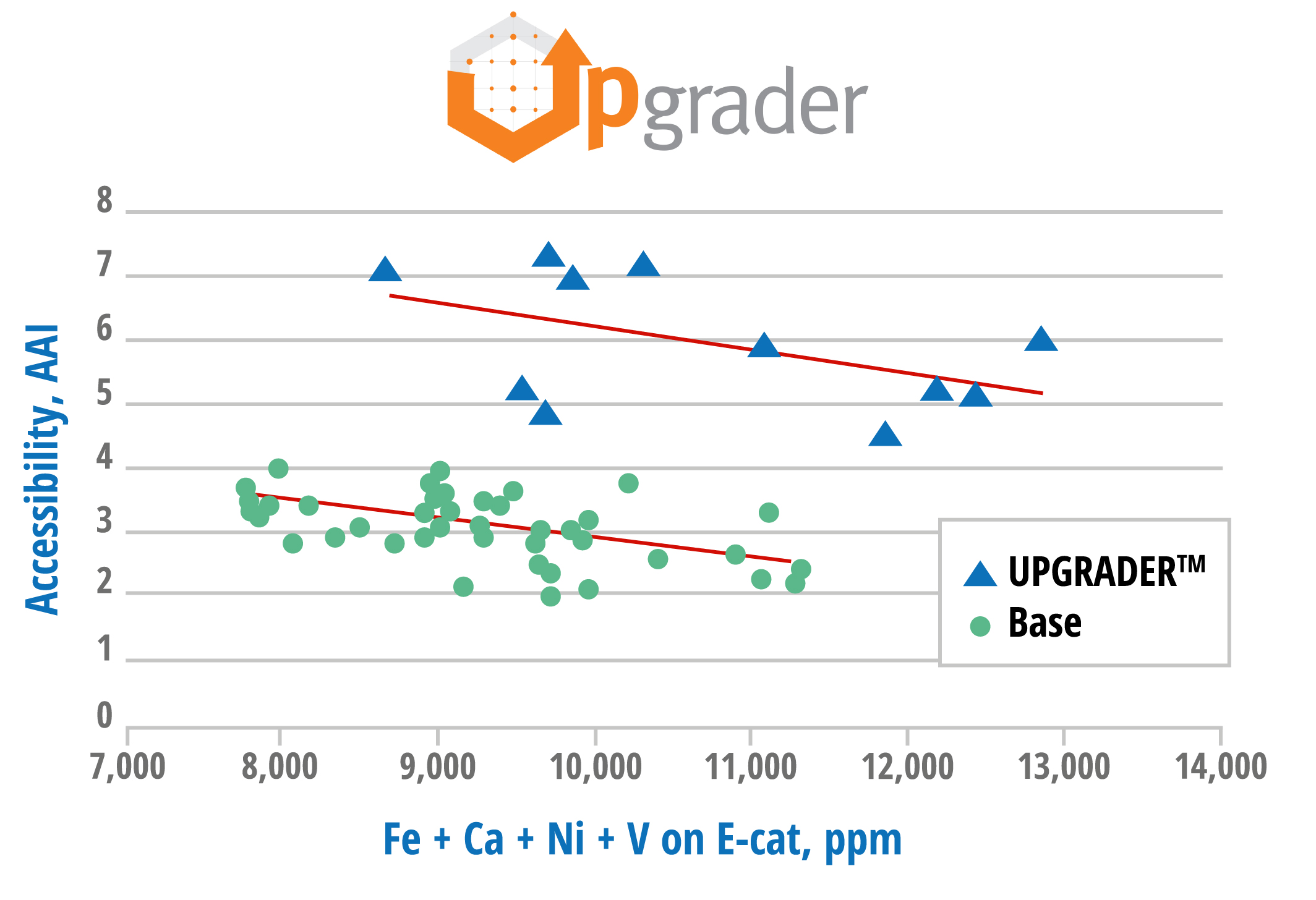

The increasing presence of iron (Fe) in processed feeds has generated significant impacts on catalytic performance in FCC units. Market data indicates a progressive increase in the average iron content in the equilibrium catalysts (ECAT) over the past few years in South America. This metallic contamination is associated with difficulties in fluidization, reduced accessibility and additional formation of coke and hydrogen, compromising operational stability and unit yields. The UPGRADER™ family, however, was designed with optimized pore architecture, ensuring high accessibility even in scenarios with high metal feeds.

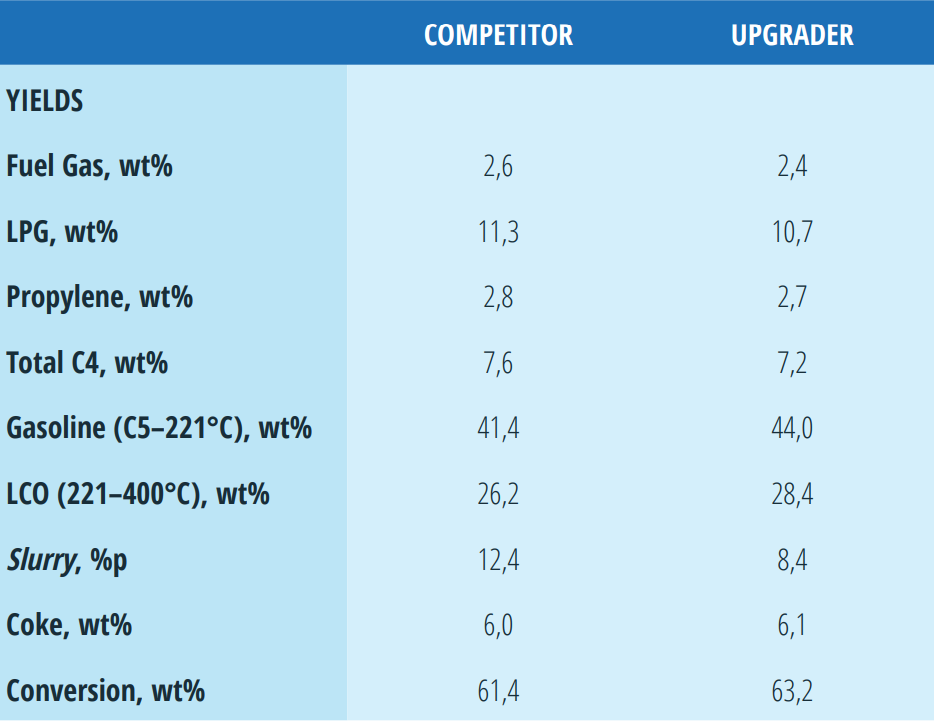

Tests conducted with Ecats containing 0,5% weight of added iron demonstrated that the UPGRADER™ shows better performance for the same iron concentration when compared to other catalysts available on the market, highlighting lower Slurry yields, higher gasoline and LCO production and greater total weight conversion. This resilience against iron is the result of advanced matrix design, which minimizes the negative effects of metal contamination through a pore engineering that favors diffusion, even with blockages or surface deposition of Fe.

Graph 2 – AAI UPGRADER versus a base catalyst.

Source – FCC S.A.

The central concept of UPGRADER™ technology is to provide high intraparticle diffusion, even for molecules with high molecular weight. This is made possible through an optimized porous structure, which significantly increases the Ketjen Accessibility Index (KAI) – a parameter that directly measures the catalyst's ability to allow access and effective cracking of heavy fractions. Studies show thatUPGRADER™ exhibits KAI values up to 2.5 times higher compared to other catalysts, highlighting its superior performance.

In addition to high accessibility, the UPGRADER™ family incorporates adjustments in the formulation of the catalytic matrix to further improve coke selectivity and provide superior resistance to metal deposition, contributing to operational stability and a longer catalyst lifespan. This allows the refiner to operate with greater severity, to process more challenging feeds or to increase the feed rate without compromising the unit’s integrity.

Different industrial tests in refineries in South America have demonstrated the commercial benefits of the UPGRADER™ technology. Compared to competing catalysts, UPGRADER™ enabled:

- Reduction of up to 33% in slurry yield, promoting greater LCO production for the diesel pool.

- Increase in total conversion by up to 3.3% in weight, with gains distributed among gasoline, LCO, and LPG.

- Lower coke formation, contributing to the reduction of carbon emissions per barrel of processed oil.

- Improvement in the olefinicity of light products, enhancing the quality of the gasoline pool.

Table 1 – Improvement potential of the UPGRADER in an RFCC unit.

Source – FCC S.A.

In one of the commercial applications, the replacement of a base catalyst withUPGRADER™ in a unit working with an average of10,000 ppm of Ni + V in the Ecat resulted in a significant reduction of the slurry yield and an increase in the conversion of bottoms to LCO and gasoline, with a direct impact on the unit's profitability – reaching gains of up to USD 1,51/bbl processed.

The UPGRADER™ technology proves to be especially effective in FCC units that operate with:

- High levels of metals (Ni, V, Fe);

- Low-quality feeds (e.g.: heavy feeds, atmospheric and vacuum residues);

- Operational limitations in the energy balance of the air blower;

- Objectives for maximizing liquid products (gasoline, LCO, LPG).

What did you make of the publication?